Welcome to the wonderful world of homemade body lotion, where simplicity and skincare come together to create nourishing and luxurious products tailored to your unique needs. Whether you’re seeking hydration, soothing relief, or simply indulging in self-care, crafting your own lotions allows you to harness the power of natural ingredients and customize formulations to suit your preferences.

Together, we’ll explore the art of lotion making, from selecting high-quality ingredients to mastering essential techniques. Along the way, we’ll delve into the science of skincare, understanding how each component contributes to the overall efficacy and feel of the final product.

Get ready to unleash your creativity, experiment with aromatic scents and botanical extracts, and embark on a journey of self-discovery and pampering. With each batch of body lotion you create, you’ll not only nourish your skin but also nurture your creative side, embracing the beauty of simplicity and the joy of homemade skincare.

Let’s dive in and begin this enchanting journey into the captivating world of homemade body lotion together!

Table of Contents

Prefer to watch this project instead of reading it?

Certain links on this website are affiliate links, as I am an associate. Clicking on these links and making a purchase may earn me a small commission. Rest assured, there is no extra cost to you.

Understanding Body Lotion Ingredients

Making your own lotion becomes much easier once you understand the essential ingredients that form its base. Here’s a breakdown:

Water

Water serves as the primary component and base of lotion formulations, playing a crucial role in hydrating the skin and providing a medium for other ingredients. Here’s a breakdown of its importance and common substitutes:

Importance of Water:

- Hydration: Water is essential for moisturizing the skin, as it provides moisture to the upper layers of the skin, keeping it hydrated and supple.

- Base Ingredient: Water serves as the base of lotion recipes, forming the majority of the formulation. It provides a neutral and lightweight medium for incorporating other active ingredients.

Common Water Substitutes:

- Aloe Vera Juice: Aloe vera juice is a popular substitute for water in lotion formulations. It offers additional skin-soothing and moisturizing properties, making it suitable for sensitive or dry skin types.

- Hydrosols (Floral Waters): Hydrosols, also known as floral waters, are aromatic waters produced during the steam distillation of plant materials for essential oil extraction. They contain trace amounts of essential oils and botanical compounds, providing both hydration and therapeutic benefits to the skin.

Considerations for Water Substitutes:

- When substituting water with alternative ingredients such as aloe vera juice or hydrosols, consider their specific properties and benefits for the skin.

- Ensure that the chosen substitute complements the overall formulation and aligns with the desired skincare goals.

- Take into account any additional considerations, such as pH balance, stability, and preservation requirements, when formulating with water substitutes.

By incorporating water or suitable alternatives into lotion formulations, you can effectively hydrate the skin and create nourishing and moisturizing products tailored to specific skincare needs. Each ingredient choice contributes to the overall performance and effectiveness of the lotion formulation.

Humectants

Humectants are crucial ingredients in lotions as they help to attract moisture to the skin, keeping it hydrated and moisturized. Here are some popular humectants commonly used in skincare formulations:

- Glycerin: Glycerin is a versatile humectant that draws moisture from the air and helps retain it in the skin, keeping it hydrated and supple. It also has emollient properties, making the skin soft and smooth.

- Hyaluronic Acid: Known for its exceptional ability to hold water, hyaluronic acid can retain up to 1000 times its weight in water, providing intense hydration to the skin and reducing the appearance of fine lines and wrinkles.

- Panthenol (Vitamin B5): Panthenol is a provitamin of B5 that penetrates deeply into the skin, where it attracts and holds moisture, helping to hydrate and soothe dry, irritated skin. It also has anti-inflammatory properties, making it beneficial for sensitive skin.

- Sodium Lactate: Sodium lactate is a natural humectant derived from the fermentation of sugars. It helps to attract moisture to the skin and maintain its natural moisture barrier, keeping it soft and hydrated.

- Hydrolyzed Protein: Hydrolyzed proteins, such as hydrolyzed collagen or keratin, have humectant properties that help to moisturize and strengthen the skin. They also promote elasticity and firmness, improving the overall appearance of the skin.

Incorporating humectants into body lotion formulations helps to replenish and maintain the skin’s moisture levels, leaving it feeling hydrated, smooth, and healthy. By selecting the right combination of humectants, you can tailor your lotion to address specific skincare needs and achieve optimal hydration results.

Emollients

Emollients are key ingredients in body lotions as they play a vital role in moisturizing and softening the skin. They work by providing hydration to the upper layers of the skin, thereby smoothing and softening its texture. Here are the common types of emollients used in lotion formulations:

- Plant-Based Oils: These oils are derived from various plants and seeds and are rich in fatty acids and nutrients that nourish the skin. Common examples include:

- Butters: Butters are rich, creamy substances extracted from nuts or seeds. They are highly moisturizing and provide a protective barrier on the skin. Common examples include:

- Fatty Acids and Alcohols: These compounds are derived from natural sources and help to hydrate and soften the skin. Examples include:

- Esters: Esters are compounds formed by the reaction between an alcohol and an acid. They are lightweight and provide a silky, smooth feel to the skin. An example is:

Each type of emollient offers unique benefits and properties, allowing formulators to tailor their lotion formulations to specific skin types and preferences. By incorporating a variety of emollients into a lotion, you can provide effective hydration and nourishment, resulting in soft, smooth, and healthy-looking skin.

Emulsifier, Stabilizers, and Preservatives

Emulsifier

Emulsifiers are essential ingredients in lotion formulations as they enable the combination of oil and water components to create a stable emulsion. Here’s a breakdown of their role and commonly used options in body lotion:

Role of Emulsifiers:

- Combining Oil and Water: Emulsifiers have surfactant properties, allowing them to interact with both oil and water components in the formulation. This enables the creation of a uniform mixture or emulsion, resulting in a creamy consistency for the lotion.

- Stabilizing Emulsion: By reducing the surface tension between oil and water molecules, emulsifiers help stabilize the emulsion, preventing separation and ensuring long-term stability of the product.

Commonly Used Emulsifiers for Body Lotions:

- Emulsifying Wax: This is a widely used emulsifier in lotion formulations. It typically contains a blend of fatty alcohols and emulsifying agents, which facilitate the formation of stable oil-in-water emulsions.

- Olivem 1000: Derived from olives, Olivem 1000 is another popular emulsifier used in skincare formulations. It offers excellent emulsifying properties and helps create lightweight and moisturizing lotions.

Note on Emulsifying Waxes:

- Despite the name “wax,” emulsifying waxes are not actually waxes. Instead, they are surfactants that contain fatty alcohols. These ingredients play a crucial role in emulsion formation and stabilization.

Considerations for Emulsifiers:

- When selecting an emulsifier for your lotion formulation, consider factors such as compatibility with other ingredients, desired texture, and stability requirements.

- Follow recommended usage rates provided by the manufacturer to ensure proper emulsion formation without compromising the integrity of the final product.

Thickener / stabilizer

Thickeners and stabilizers play a crucial role in lotion formulations by improving stability and enhancing the sensory experience. Here’s a breakdown of their functions and commonly used options:

- Functions:

- Improving Stability: Thickeners and stabilizers help prevent the separation of water and oils in lotions, leading to a more stable product.

- Enhancing Texture: These ingredients contribute to the overall feel and texture of the lotion, providing a smooth and luxurious sensory experience.

- Increasing Viscosity: Thickening agents increase the viscosity of the lotion, giving it a thicker consistency and better spreadability.

- Interchangeable Role:

- Thickeners and stabilizers often serve dual functions, hence why the terms are sometimes used interchangeably. They not only thicken the formulation but also contribute to its stability.

- Commonly Used Options:

- Xanthan Gum: This natural polysaccharide is commonly used as a thickener and stabilizer in lotions. It helps create a smooth texture and improve viscosity.

- Guar Gum: Another natural thickening agent derived from guar beans, guar gum helps enhance the viscosity and stability of lotions.

- Cetyl alcohol: Cetyl alcohol acts as both a thickener and an emollient in lotions. It provides a creamy texture and helps stabilize the formulation.

- Cetearyl alcohol: Similar to cetyl alcohol, cetearyl alcohol serves as a thickener and stabilizer while also providing emollient properties to the lotion.

- Considerations:

- When selecting a thickener/stabilizer for your lotion formulation, consider factors such as compatibility with other ingredients, desired viscosity, and sensory attributes.

- Follow recommended usage rates to ensure optimal performance and stability without compromising the texture or feel of the lotion.

Preservative

- Importance of Preservatives: Preservatives are necessary in lotions to inhibit the growth of mold, bacteria, and fungi. Without preservatives, the presence of water in the formulation provides an ideal environment for microbial proliferation, leading to product spoilage and potentially harmful effects on the skin.

- Broad Spectrum Preservatives: When formulating lotions, it’s essential to use broad-spectrum preservatives capable of effectively inhibiting a wide range of microorganisms. This ensures comprehensive protection against microbial contamination.

- Commonly Used Preservatives:

- Germall Plus: This is a broad-spectrum preservative system. It is effective against bacteria, yeast, and mold.

- Geogard Ultra: Geogard Ultra is another broad-spectrum preservative system derived from natural sources. It typically contains dehydroacetic acid and benzyl alcohol, providing protection against bacteria, yeast, and mold.

- Selection Considerations: When choosing a preservative for your lotion formulation, consider factors such as efficacy, compatibility with other ingredients, pH stability, and regulatory compliance. Additionally, opt for preservatives that are suitable for natural or organic formulations if desired.

- Usage and Dosage: Follow the manufacturer’s recommended usage rates and guidelines for incorporating preservatives into your lotion formulation. Over- or under-dosing of preservatives can compromise efficacy and product safety.

- Testing and Stability: Conduct stability and microbial challenge tests to ensure the effectiveness of the chosen preservative system in preventing microbial contamination throughout the product’s shelf life.

Antioxidant

- Antioxidant Properties: Vitamin E oil is a powerful antioxidant that helps to prevent the oxidation of oils and fats in skincare products. Oxidation is a natural process that occurs when oils are exposed to air, leading to the formation of free radicals and the degradation of oils, resulting in rancidity. Vitamin E helps to neutralize these free radicals, thereby extending the shelf life of the oils and maintaining their quality.

- Extending Shelf Life: By preventing oxidation, vitamin E oil helps to extend the shelf life of skincare products containing oils and butters. This ensures that the product remains fresh and effective for a longer period, reducing the likelihood of rancidity and spoilage.

- Skin Benefits: In addition to its role as an antioxidant, vitamin E oil offers numerous benefits for the skin. It helps to moisturize and nourish the skin, leaving it feeling soft and smooth. Vitamin E also has anti-inflammatory properties, which can help soothe and calm irritated or sensitive skin. Furthermore, it protects the skin from environmental stressors and UV damage, making it an excellent ingredient for maintaining skin health and vitality.

- Protection from Free Radicals: Free radicals are unstable molecules that can damage skin cells and contribute to premature aging. Vitamin E oil helps to neutralize these free radicals, protecting the skin from oxidative stress and reducing the appearance of fine lines, wrinkles, and other signs of aging.

How to make Body Lotion

Now that we have our ingredients down we can go ahead and make our lotion.

We have two separate phases that are heated: water phase and oil phase.

- The water and the water soluble ingredients go into water phase.

- Oils and oil soluble ingredients go into oil phase.

Water phase

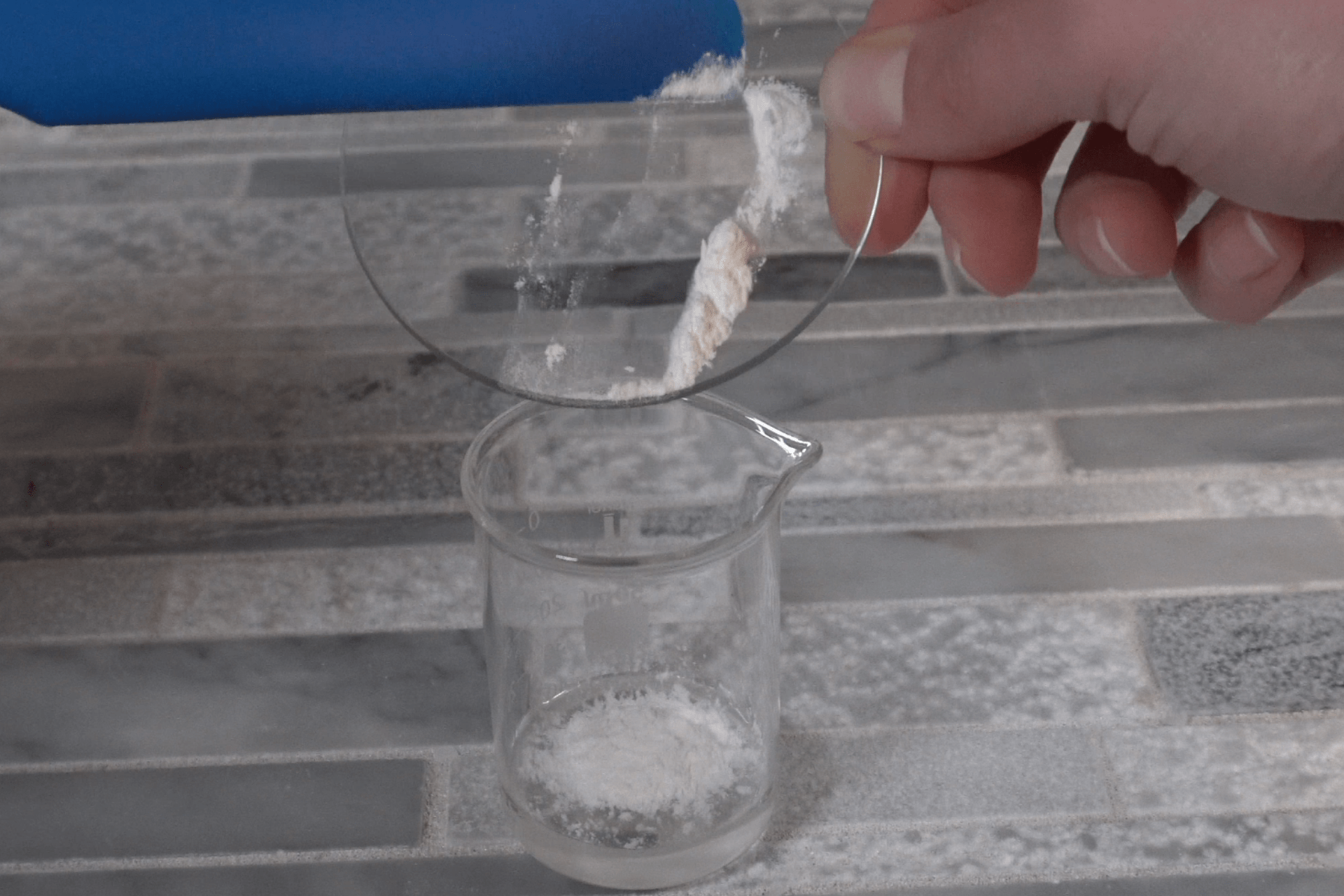

- Preparation: Before starting, ensure you have the necessary ingredients: xanthan gum, glycerin, water, and optional hydrosol or aloe juice.

- Mixing the Slurry:

- In a small container, measure out the required amount of glycerin.

- Gradually sprinkle the xanthan gum over the glycerin while stirring continuously. This helps to disperse the xanthan gum evenly and prevent clumping.

- Continue stirring until a smooth slurry is formed. This step ensures that the xanthan gum is thoroughly dispersed and hydrated before adding it to the water phase.

- Incorporating into Water:

- Pour the water (and hydrosol or aloe juice if using) into a larger mixing container.

- Slowly add the xanthan gum-glycerin slurry to the water phase while stirring continuously. Adding the slurry gradually helps to prevent clumping and ensures even dispersion throughout the water phase.

- Mixing Thoroughly:

- Once all the slurry has been added, continue stirring the mixture thoroughly to ensure that the xanthan gum is fully dispersed and hydrated. This helps to achieve the desired viscosity and texture in the final product.

Oil Phase

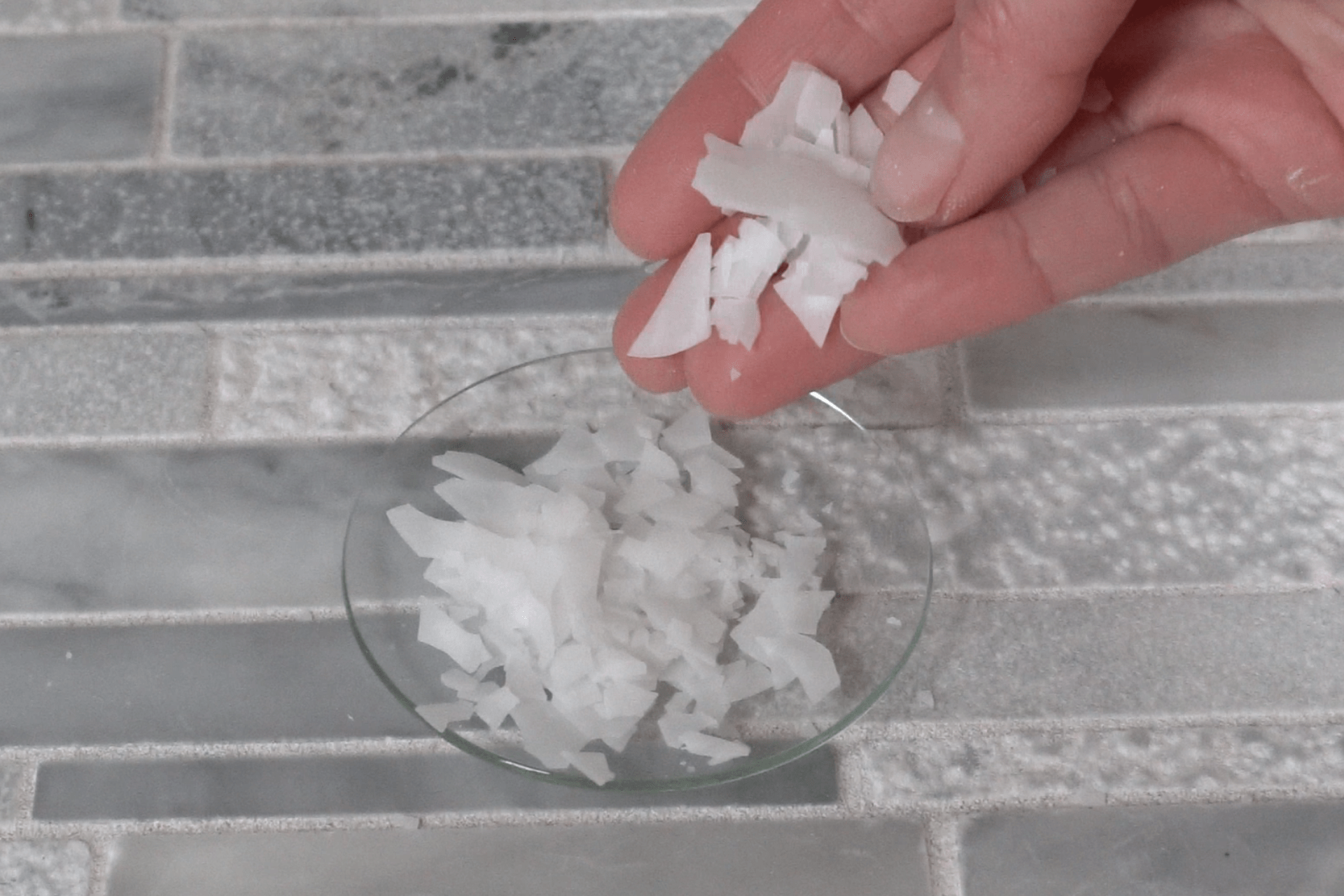

- Gather Ingredients: Collect the following ingredients for the oil phase:

- Shea butter

- Fractionated coconut oil

- Olivem 1000

- Cetyl alcohol

- Select Heat-Safe Container: Choose a heat-safe container large enough to accommodate all the ingredients. Glass or stainless steel containers are commonly used for this purpose.

- Combine Ingredients: In the heat-safe container, add the oil phase ingredients.

Heating the Water and Oil Phase

- Double Boiler Setup: Set up a double boiler by placing a heat-resistant bowl containing the oil phase ingredients and another containing the water phase ingredients over a pot with water.

- Gentle Heating: Heat the water and oil phases gently and slowly. Rapid heating can lead to the degradation of heat-sensitive ingredients and affect the overall quality of the final product. The double boiler method provides gentle and even heat distribution, minimizing the risk of overheating.

- Melting Ingredients: Allow the ingredients in both phases to melt completely. Stir occasionally to ensure uniform heating and melting. It’s essential to heat both phases to the same temperature to prevent any issues with phase separation later on.

- Temperature Control: Both phases should reach the same temperature before proceeding to the next steps. This ensures that the oils remain in a liquid state and can effectively emulsify with the water phase.

- Maintaining Temperature Parity: Keeping both phases at the same temperature is critical. If one phase is significantly warmer than the other, it can lead to difficulties in forming a stable emulsion. The double boiler method helps maintain temperature parity between the phases.

Combining the oil and water.

- Prepare Containers: After removing both the oil and water phases from the double boiler, wipe the containers to ensure they are dry and free from any residual water. Any water left on the containers could contaminate the lotion.

- Pouring Phases: Pour the water phase into the oil phase or vice versa, it is per your preference.

- Emulsion Blender: Use an emulsion blender (also known as a stick blender) to mix the two phases together. The emulsion blender helps to create a stable emulsion by breaking the oil droplets into smaller sizes and dispersing them evenly throughout the water phase. It’s essential to blend at a high shear rate to achieve proper emulsification.

- Blend with High Shear: Blend the mixture for approximately 60 seconds initially. The goal is to blend as much as possible while incorporating as little air as possible into the mixture. Air bubbles can affect the texture and stability of the final product.

- Hand Stirring: After blending, hand stir the mixture for a few minutes. This helps ensure thorough mixing and promotes the formation of a stable emulsion. Repeat the blending and hand stirring process several times until a smooth and uniform emulsion is achieved.

- Repeat Cycle: Repeat the process of alternating between stick blending and hand stirring for a few cycles. Each cycle helps to improve emulsion stability and ensure uniform distribution of ingredients.

- Check Emulsion Stability: Once the emulsion is formed, it’s important to check its stability over time. Allow the mixture to cool to room temperature and observe for any signs of separation or phase inversion. Conducting stability tests helps ensure the quality and effectiveness of the final product.

Cool Down Phase

The cool down phase contains all of the heat sensitive ingredients.

- Temperature Check: Ensure that the mixture has cooled down to below 122°F (50°C) before adding the heat-sensitive ingredients. This can be confirmed using an infrared thermometer or by allowing the mixture to reach room temperature.

- Ingredients in the Cool Down Phase:

- Hydrolyzed collagen protein

- Hydrolyzed wheat protein

- Vitamin E oil

- Preservative

- Essential oils

- Following Manufacturer Recommendations: It’s crucial to adhere to the manufacturer’s recommendations for each ingredient. This includes any specified temperature ranges for incorporation and suggested usage rates.

- Determining Essential Oil Usage Rate: While essential oils are typically used in small amounts, it’s important to calculate the appropriate percentage for your formulation. A common guideline is to use no more than 1% of essential oils in a leave-in body lotion. This ensures safety and avoids potential skin irritation.

- Mixing: Once all the ingredients are added, mix thoroughly to ensure even distribution.

- Testing: After formulation, it’s advisable to conduct stability and compatibility tests to ensure the product’s efficacy, safety, and shelf-life.

Body Lotion Recipe

Equipment

- Scale

Ingredients

Water Phase

- 7.26 ounce | 72.6% Distilled Water

- 0.30 ounce | 3% Vegetable Glycerin

- 0.04 ounce | 0.4% Xanthan Gum

Oil Phase

- 0.80 ounce | 8% Shea butter

- 0.15 ounce | 1.5% Cetearyl Alcohol

- 0.30 ounce | 3% Olivem 1000

- 0.80 ounce | 8% Fractionated Coconut Oil

Cool Down

- 0.10 ounce | 1% Hydrolyzed Wheat Protein

- 0.05 ounce | 0.5% Hydrolyzed Collagen

- 0.10 ounce | 1% Vitamin E Oil

- 0.05 ounce | 0.5% Germall Plus

- 0.10 ounce | 1% Essential oils

Instructions

Water Phase

- Gradually sprinkle the xanthan gum over the glycerin while stirring continuously.

- Slowly add the xanthan gum-glycerin slurry to the water phase while stirring continuously. Then Mix.

Oil Phase

- In the heat-safe container, add the oil phase ingredients.

Heat

- Heat the water and oil phases gently and slowly on a double boiler.

Combine

- Pour the water phase into the oil phase.

- Use an emulsion blender (also known as a stick blender) to mix the two phases together.

Cool Dowm

- After it has cooled down to below 122°F (50°C) add the heat-sensitive ingredients. Mix well.

- Package and enjoy!

Summer Rain Community

Don’t miss out on your journey to crafting exceptional skincare at home! You can subscribe to my blog for a treasure trove of DIY skincare recipes, insightful tips, and expert guidance.

Subscribe to our newsletter!

Subscribe to our newsletter!

Join the community of skincare enthusiasts! Follow us on social media to dive deeper into the world of homemade skincare. Discover exclusive content, behind-the-scenes insights, and connect with like-minded individuals passionate about nurturing their skin naturally.

Facebook: https://facebook.com/summerrain.website/

Pinterest: https://www.pinterest.com/summerrainblog/

Patreon: https://www.patreon.com/Summerraindiy

TikTok: https://www.tiktok.com/@summerraindiy

Let’s embark on this exciting skincare adventure together—subscribe, follow, and elevate your DIY skincare game!